Hi -

I have a CSV and pump newly installed as described below. The pressure never gets high enough to turn off the pump. IE - the pressure never reaches the cut-out pressure of 70psi. The highest the pressure gets is 64-66psi.

Troubleshooting -

Confirmed the check valve is holding pressure.

Confirmed there are no leaks on the discharge side.

Adjusted the CSV, even to the point of turning the set screw almost all the way in.

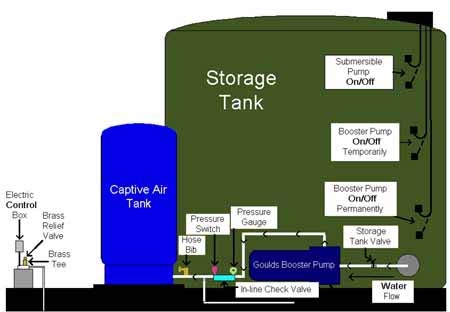

500 gl holding tank 6' H x 4' Diameter

|

~60' 2" pvc pipe

|

1 1/4" FLOMATIC 4202SS2 check valve

|

Goulds HSC15, Multi-Stage Centrifugal Pump, 1-1/2 HP, 2 Stages, 1-1/4" Suction, 1" Discharge

|

~5" 1" stainless steel pipe

|

PK1A PSIDE-KICK Pressure Tank Kit

10 gallon tank

I made a support to hold the tank horizontal

The bladder pressure is about 48psi

50-70 pressure switch

I am at a loss. The only thing I can think of is that the pump is unable to build pressure to 70psi. Is there anything I am missing or should check?

If the pump is unable to build pressure to 70psi - I will then need to troubleshoot that. I thought the Goulds HSC15 pump could go to 125psi.

Any direction is greatly appreciated.

Thanks,

Joe