Eliminate Water Hammer

with

Transient Wave Canceling Technology

Many recent articles have explained the necessity of finding and repairing leaks in water mains. Leaks in water lines can be anything from tiny stress fractures to blow outs that requires rescues by helicopter. Either way these leaks waste millions of gallons of our precious fresh water everyday. Without first addressing the cause of the problem, finding and repairing leaks can be a futile effort.

Corrosion and age of the pipe causes some leaks but, the main cause of leaks in a piping system is water hammer. Once leaks occur, they act as pressure relief for the water hammer. Repairing leaks will leave no place for the water hammer to vent, which will cause new leaks to reappear, as fast as the old ones are repaired. Repairing leaks can be a money pit, if we don't stop the water hammer that caused the leaks in the first place.

Water hammer causes pressure spikes that can be 10 times higher than normal operating pressure. Transient pressure waves cause water hammer. Because of the incompressibility of water, transient pressure waves travel through a pipe line at speeds of 3,000 to 8,000 feet per second. When these supersonic waves hit dead ends, elbows, or tees, they create water hammer. These waves bounce off of dead ends, elbows, and tees and can ricochet back and forth many times before subsiding. A single wave can cause many water hammer events, which is the main cause of destruction for pipe and fittings.

Transient pressure waves and the subsequent water hammer can be created on the demand or the supply side of the system. On the demand side, slow opening and slow closing valves should be employed, and water hammer arresters should be installed at strategic locations. However the majority of water hammer problems are created on the supply side of the system. Most water hammer problems occur as pumps are started and stopped to allow water towers and hydro pneumatic tanks to fill and drain, or when pump control systems react too fast or too slowly.

When a pump is started, a transient pressure wave is created that travels throughout the entire plumbing system. When a pump is stopped, the water continues to travel or stretch forward, which creates a negative pressure. The water then snaps back like a rubber band, which instantly changes the negative pressure to a spike of positive pressure.

These swings from negative to positive pressures contract and expand the pipe line, and water hammer repetitively pounds away at the pipe, fittings, and thrust blocks. In the worst cases, elbows, tees, pipe, and valves can be blown off completely and major leaks spring up like geysers. At the very least, tiny stress fractures and small cracks appear in thousands of places in the pipe system. Either way millions of gallons of water is lost through breaks and leaks, while at the same time, negative pressure waves can draw contaminants into the pipe line.

One of the first rules we learn in life, is that a body in motion wants to stay in motion, and a body at rest wants to stay at rest. Water in a pipe line takes this law of physics to the extreme. It should stand to reason that keeping a pump running continuously, should help eliminate transients and water hammer, verses starting and stopping the pump numerous times. To keep the pump running continuously, Pump Control Valves, Variable Frequency Drives (VFD's), or other devices must vary the flow rate of a pump to match the usage. However, the slightest delay in response from slow opening and slow closing valves, VFD's, and soft starters can actually cause transient waves, as much or more than too fast of a response. Delayed reactions can even accentuate and perpetuate transients and water hammer, making matters worse.

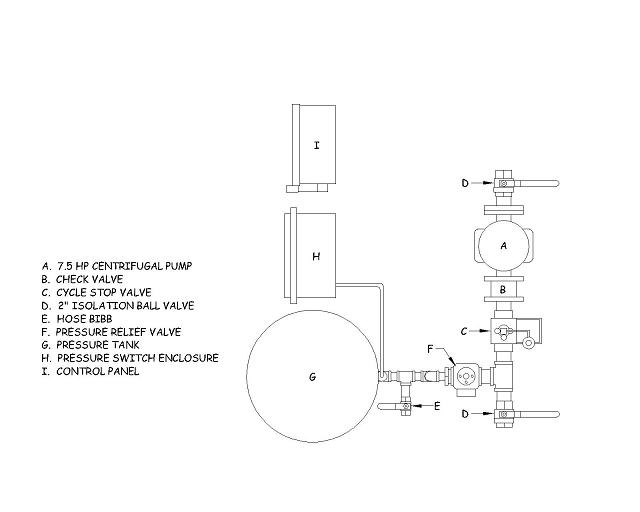

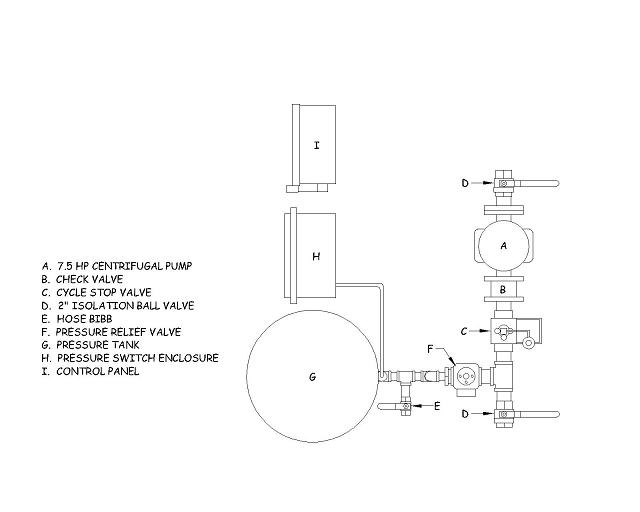

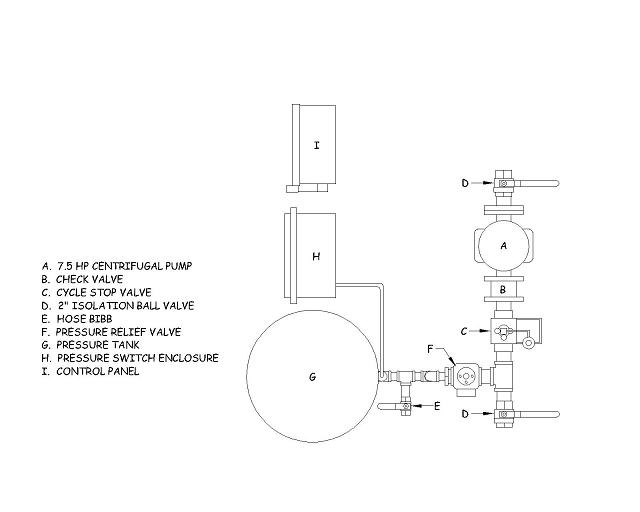

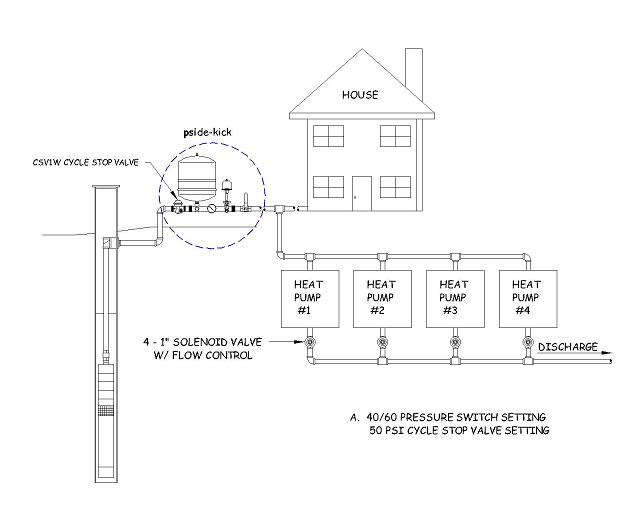

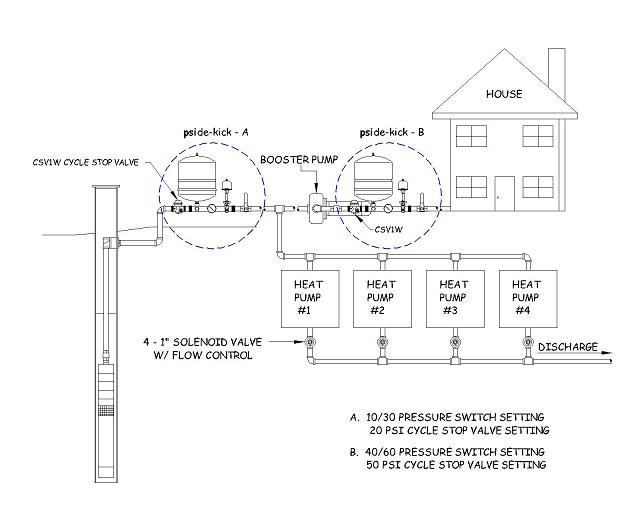

Cycle Stop Valves or CSV's offer a simple solution to the problem. CSV's are designed to vary the flow from the pump to match the usage, which keeps a pump running constantly. Working on a pressure reducing principal, they continually regulate the flow from the pump by maintaining a constant pressure. This design never allows the valve to completely close against the seat. Never completely closing, and not having to pop open from a closed position, eliminates "hunting" or pulsing of the pressure, that is known to fully closing type valves.

Because they never completely close, the valve travel or reaction speed of the CSV can be increased exponentially, allowing extremely fast reactions to any changes in system pressure. This cancels out transient pressure waves much the same way as noise canceling technology cancels out noise. When an increase in system pressure is sensed, these valves instantly decrease the flow rate of the pump. Likewise when they sense a decrease in system pressure, these valves instantly increase the flow from the pump. When a negative pressure wave is instantly met with positive pressure, and positive pressure wave is instantly met with reduced pressure, transient waves are cancelled out.

Slow opening and slow closing pump control valves, even other so called "Constant Pressure Valves", can actually cause transient pressure waves. Slow opening of a control valve will cause the pressure to pulse, starting a transient wave, no matter how slow the control valve is opened. Closing a control valve before the pump is shut off, will cause a negative pressure wave, no matter how slow the valve is closed.

Soft starting and stopping of the pump can cause the same transient waves as slow opening and slow closing control valves. When a large demand is opened, waiting on a soft start or slow opening valve can further accentuate transient pressure waves and water hammer. When a large demand is closed, waiting even a fraction of a second on a soft stop or a slow closing control valve, can cause tremendous spikes in pressure.

Variable Frequency Drives or VFD's can also be programmed to maintain a constant pressure. A VFD system can be programmed to respond very fast. However, a VFD is usually programmed to adjust the pumps speed only every 3 to 5 seconds, or even longer. The quicker the response time programmed into the VFD, the more "hunting" or bouncing of pressure is seen and felt. Even if a VFD is programmed to respond quickly, it takes a fraction of a second for the transducer to see the pressure change, send a signal to the controller, and for the controller to change the speed of the motor/pump. By this time the transient wave, moving at thousands of feet per second, has already bounced off and is causing more destruction several thousand feet down the pipe line.

Programming a delay into a VFD or standard pump control valve, is much like swinging at a baseball, after the ball is already hit the catcher's mitt. The effort is too little and too late. Increasing the speed of a VFD or standard pump control valve will cause "hunting" and pulsing of the pressure. Even if it were possible for them to operate very fast, the reaction time would be just a bit off. Even the slightest bit off, is like landing on a trampoline a split second after someone else. It causes a catastrophic collision and shoots the person (pressure) extremely high.

Transient pressure waves cause water hammer. Water hammer causes pipe line breaks. Pipe line breaks are time consuming, expensive to repair, waste millions of gallons of our precious fresh water everyday, and allow contamination to enter our clean water supplies. It is a futile effort, and a waste of time and money, to repair any leaks before the root cause of the problem has been identified and corrected.

Wasting water is simply unacceptable. There is a solution. Cycle Stop Valves are the only pump control with transient wave canceling technology. Cycle Stop Valves have proven to eliminate water hammer and line breaks in numerous water systems, large or small. Don't fix another leak without first solving the problem that caused it in the first place. Every water pump system needs the wave canceling technology of a Cycle Stop Valve.

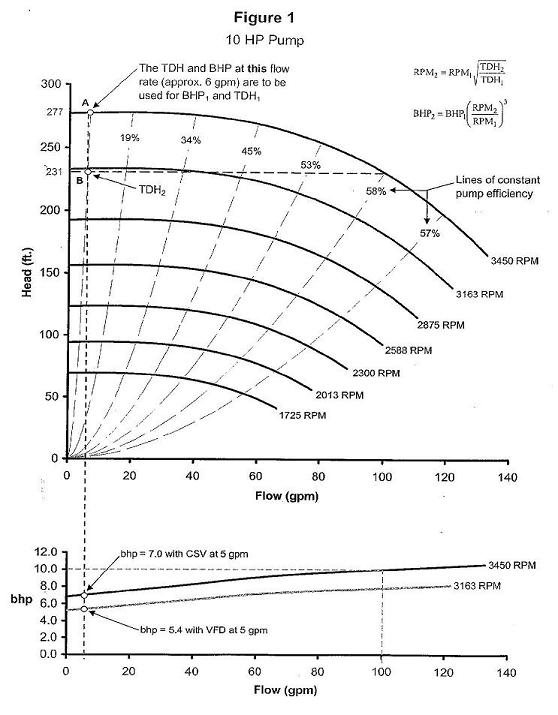

(Tµn2).

(Tµn2).  (Pµn3), as the power requirement is reduced in the same way.

(Pµn3), as the power requirement is reduced in the same way.