A two stage heat pump needs 10 GPM for each stage plu another 10 GPM for the house supply. The heat pump will run on stage 1 at 10 GPM for 4,000 hours per year. It will run on stage 2 at 20 GPM for 2,000 hours per year. Then we figure stage 2 at 20 GPM and the house requiring another 10 GPM for a total of 30 GPM running 500 hours a year. The well is 100' to pumping level and the house requires 60 PSI.

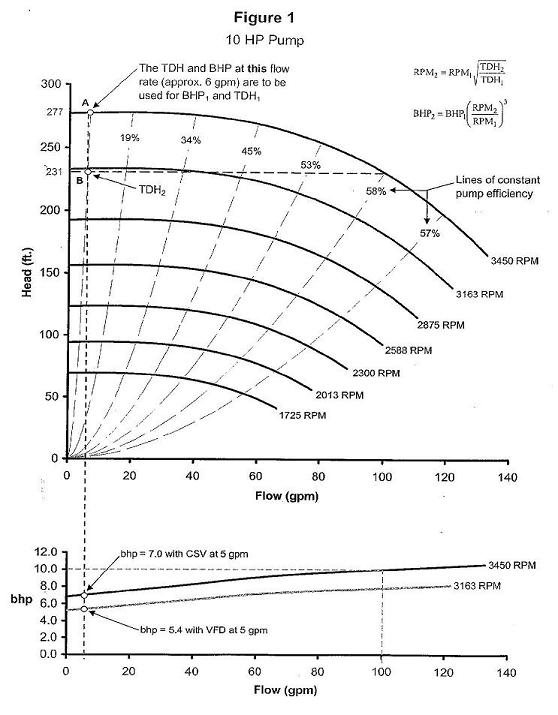

Figuring a one pump system to handle multiple demands. I cannot get efficiency curves for 4" submersible pumps. I would like to post a curve below by Grundfos Pump Company that they made to explain the differences between VFD and CSV. They used a 10 HP pump at 231' of head. We can use this curve to figure the difference of power in percentage, and scale down to a 2 HP, which is what it would take for the system you describe.

Using CSV;

This curve shows 10 HP required for 105 GPM at 231' at 3450 RPM.

At 2/3rds flow 8 HP required for 70 GPM at 231' at 3450 RPM.

At 1/3rd flow 5 HP required for 35 GPM at 231' at 3450 RPM

Using VFD;

At full flow 10.5 HP required for 105 GPM at 231' at 3450 RPM.

At 2/3rds flow 7.7 HP required for 70 GPM at 231' at 3163 RPM.

At 1/3rd flow 3 HP required for 35 GPM at 231' at 2886 RPM.

Full Flow;

CSV 100% of HP

VFD 105% of HP

2/3rds flow;

CSV 80% of HP

VFD 77% of HP

1/3rd flow;

CSV 50% of HP

VFD 30% of HP

Using a 2 HP submersible to produce 1/3rd flow of 10 GPM for 4,000 hours at .10 per KW.

CSV $459.00

VFD $276.00

Difference of $183.00

2 HP submersible to produce 2/3rds flow of 20 GPM for 2,000 hours at .10 per KW.

CSV $368.00

VFD $354.00

Difference of $ 14.00

2 HP submersible to produce full flow of 30 GPM for 500 hours at .10 per KW.

CSV $115.00

VFD $121.00

Difference of $ -6.00

Total difference of $191.00 per year or $15.91 per month. Figuring a VFD for a 2 HP at about $1,000.00, that would be more than a 5 year pay out. If the VFD last longer than 5 years there are some savings. If the VFD last less than 5 years, you never break even.

The CSV has proven to increase the life of pump systems.

The VFD has proven to shorten the life of pump systems.

I got the cost per KW form this web site;

http://www.productiveenergy.com/calculator/pump.aspWhich is also where I got this interesting quote.

"Energy savings for your system may be toward the low end of the above range, but don't forget that usually the energy savings are often small compared to production benefits of having a more reliable system. If the potential savings are towards the low end of the scale, you may not be able to afford pricier optimization options like Adjustable Speed Drives."

There are many variables such as hours of operation, percent of flow, price per KW, and cost of equipment. When the required flow rate is small the majority of the time the VFD does slightly better. When the required flow rate is high most of the time the CSV does better. When the flow rate is low half the time and high the other half, it is a wash between CSV and VFD. The largest savings are usually in making the equipment last the longest.