Marion County, Florida is using a 4" Cycle Stop Valve and an 80 gallon bladder tank to replace a 12,000 gallon hydro pneumatic tank. Several community water systems in Marion County are using Cycle Stop Valves and small bladder tanks to supply "constant pressure" to their customers. These systems are set up to be temporary, while the huge pressure tanks are off line for service and cleaning. However, it should be noticed that the system pressure is much better controlled, and the pump cycling and water hammer events have disappeared after installing the CSV's.

The first picture shows the submersible well pump being controlled by a Cycle Stop Valve and an 80 gallon pressure tank. The 12,000 gallon tank that is out of service is pictured in the background.

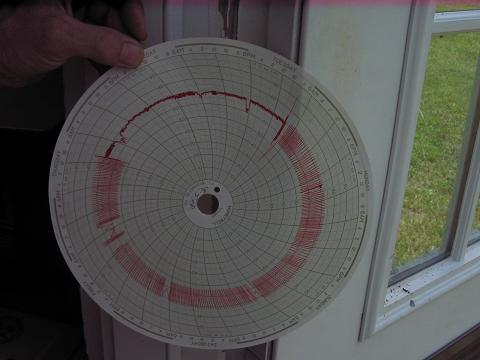

The second picture is of the pressure recording chart for a week of service. The first 5 days of this chart was with the 12,000 gallon tank, the last two days shows the recorded pressure for the CSV controlled system. In the first 5 days with the big pressure tank, there was 291 cycles. That is 2.38 cycles per hour, 57 cycles per day, or about 21,000 cycles per year. Notice the regular "heartbeat" on the graph as the pump cycles on the big pressure tank. Each "heartbeat" represents a water hammer event that happens throughout the entire system. It also represents considerable abuse on the pump, motor, controls, check valve, and piping system. The system is continually cycling between 53 and 72 PSI. This is also the variation in pressure that all the customers are feeling.

After the installation of the Cycle Stop Valve, notice that the "heartbeat" has completely disappeared. The pressure is maintained very close to a constant 60 PSI. Only a few times during peak demands does the system pressure drop to about 50 PSI. This will eliminate all the abuse usually suffered by the pump, motor, controls, and check valves, that happens with the big pressure tank system. The customers on the system will benefit from the "constant pressure" being supplied while the big pressure tank is out for service.

The operator of these systems said they will be using a CSV full time on some systems that have an even worse cycling problem. Hopefully we will also soon be getting information on the energy use before and after installing the CSV.